CONCRETE 2.0

High-Performance

Sustainable

NanoTechnology

We are the experts in Nano Silica-Based Concrete Solutions. A pioneer in the field, we have unlocked the secrets to concrete that is both high-performing and highly sustainable, through successful placement of millions of yards of concrete in both civil infrastructure and commercial structures and years of independent laboratory verification.

Reduce Excessive Chemicals in Concrete and Carbon in Our Communities.

Excessive chemicals in concrete are costly and create adverse reactions in the field. Sustainable, Carbon Reducing concrete comes from E5® Nano Silica.

E5® Nano Silica is Environmentally Friendly, Non-Hazardous, Bio-Degradable and contains ZERO VOCs. E5® increases production, improves finish quality, reduces cracking/curling and enhances durability by controlling bleeding with up to 30% greater cement hydration efficiency.

E5® Admixtures are compatible with all concrete admixtures and eliminate the need for traditional curing methods. Contractors and Homeowners gain immediate access to the concrete, saving up to 7 days over wet curing requirements. No additional water is needed during placement to maintain a workable surface. Throwing water on the surface of fresh concrete dilutes the cement paste and weakens the surface which creates pops, chips, divets and cracks in the concrete.

Adding E5® to the Mix

E5® Nano Silica Admixtures are simply added to the concrete mix at the batch plant - without the need for additional steps or time or any specialized dosing equipment.

Mixing E5® During Transit

E5® Nano Silica Admixtures influence the chemistry of the concrete immediately upon addition to, and reaction with, the mix, controlling the water of transport to reduce evaporation during transit, thereby increasing the hydration of cement and optimizing the curing process.

Finishing with E5®

E5® Nano Silica Admixtures control the water of convenience, creating a creamy fresh-state property for easy pumping, placing and finishing of concrete – reducing wear-and-tear on industrial equipment and giving control back to the finisher

Customers & Partners

E5® Nano Silica Admixtures are aqueous dispersions of nano silica with varying percentages of solids. The particles attach to the water molecules, increasing cement hydration and efficiency within the mix.

Available in a variety of grades, E5® Nano Silica Admixtures are manufactured for performance based on particle size, structure, concentration, pH, surface charge and surface modification. Solutions are blended based on regional materials.

Concrete Conversations with the CEO of E5®

Joe Shetterley

Use right and left arrows for additional video content.

On mobile, rotate horizontal.

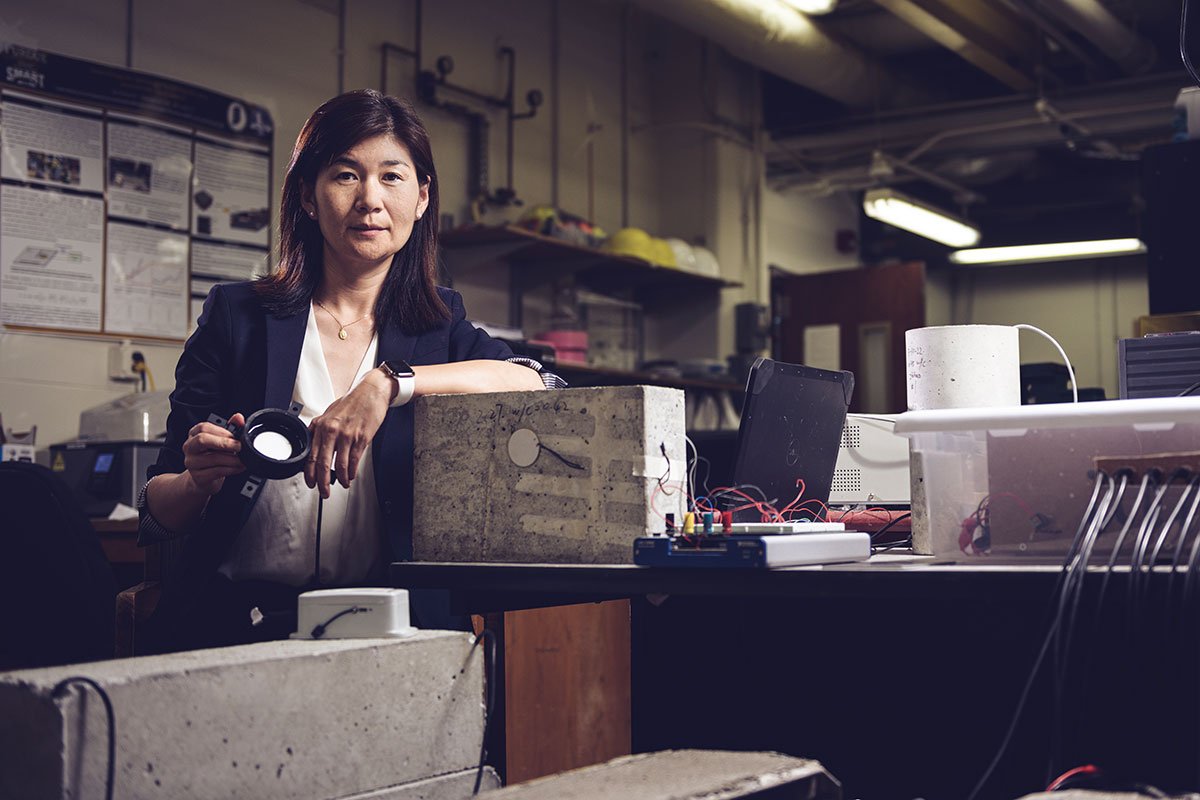

Dr. Luna Lu

Associate Dean for the Faculty | Reilly Professor, Lyles School of Civil Engineering | Inaugural Director, Center for Intelligent Infrastructure

The research group at the Lyles School of Civil Engineering at Purdue University has worked hand-in-hand with E5® to develop comprehensive and systematic testing protocols for E5® Nano Silica admixtures in concrete. Using a fundamental materials science approach, Professor Lu and her team have worked tirelessly to more fully understand the curing effect and related concrete properties achieved with E5® Nano Silica. This independent research and laboratory verification has helped generate work with DOTs all across the United States as well as validate the years of results seen in the field by the team at E5®.

E5® Binds Concrete

Binding is the process of drawing and holding together materials to form a cohesive whole. E5® Liquid Fly Ash® (LFA) is the world’s first liquid pozzolan (binding) material for use in concrete. Our proprietary blend of Nano Silica particles reacts with the calcium hydroxide produced during cement hydration to form additional binding materials (C-S-H gels) that enhance the strength and durability of concrete.

E5® Liquid Fly Ash® can replace up to 15% of cement, depending on the type of cement, and can replace or reduce the use of other supplementary cementitious materials (SCMs), such as fly ash, silica fume, micro-silica and slag. According to a study conducted by Dr. Jason Weiss in 2022, LFA is the most efficient SCM when compared to all other SCMs in the market. Additionally, LFA is readily available and consistently manufactured, providing a highly reliable source of cementitious material when other SCMs are suffering from supply shortages, quality inconsistencies and price fluctuations.

E5® Liquid Fly Ash® causes no air entrainment issues and presents no silo storage requirements, as is the case with traditional fly ash.

Additionally, E5® Liquid Fly Ash® promotes particle packing within the porous structure of concrete, resulting in molecular level densification of the concrete matrix and surface and, therefore, reduced permeability.

Dr. Jason Weiss

Professor, School of Civil and Construction Engineering Miles Lowell and Margaret Watt Edwards Distinguished Chair in Engineering

In 2022, Dr. Jason Weiss and Dr. Jon Belkowitz collaborated to examine the use E5® Liquid Fly Ash® as a nano silica additive that could potentially reduce the susceptibility of concrete to deicing salt damage. The research evaluated whether nano silica could be used to improve resistance to calcium oxychloride formation caused by deicing salts. Deicing salts, like calcium chloride and magnesium chloride, can react with water and calcium hydroxide in concrete to form an expansive product called calcium oxychloride. This project was motivated by a concern that the concrete industry could face a reduced available supply of supplementary cementitious materials for use in manufacturing concrete. The study concluded that E5® Liquid Fly Ash® had the highest pozzolanic reactivity and was the most efficient of all SCMs included in the study.

Indiana DOT (INDOT) Utilizes Combination of E5® Internal Cure® and E5® Liquid Fly Ash® Admixtures.

In 2022, as Indiana prepared for a new year of infrastructure work and highway closures, INDOT was busy vetting a promising new mix design. After rigorous testing and project evaluations, INDOT determined that E5® Liquid Fly Ash® and E5® Internal Cure®, in combination, created a highly optimal concrete mix, that eliminated the need for wet curing, allowed for a reduction of cement content, and provided additional benefits not seen with any other admixtures in the industry, including self-healing of micro-level cracking within the concrete and substantially improved bonding of cement paste to aggregates (the “weak zone” of concrete).

By using E5® Liquid Fly Ash, Indiana was able to quantifiably reduce CO2 by hundreds of tons in cement reduction. The sustainable mix design will save thousands of gallons of potable water, every year, traditionally used for wet curing.

Using this highly sustainable mix design, every year, Indiana will be able to directly reduce CO2 by thousands of tons as a result of cement reduction and save thousands of gallons of watertraditionally used for wet curing.

The Indiana Department of Transportation has implemented a solution for a greener, more efficient, concrete that will benefit the citizens of Indiana for years to come.

“E5 Internal Cure and E5 Liquid Fly Ash are a new type of concrete admixtures that have been shown to provide significant benefits during the placement of concrete and in the overall quality of the in-place concrete. Some of the benefits include improved water retention, workability, pumpability and higher pozzolanic activity, which can create higher strength and reduced permeability.

To evaluate the performance of these admixtures, an alternate curing method was developed in lieu of the water curing requirements in 702.22 Standard Specifications. This alternate curing method is to be considered for bridge decks, slab bridges and reinforced concrete bridge approaches on existing and future construction contracts.”

INDOT MEMO MAY 2021